Choosing the right custom insole supplier1 can make or break your footwear business. A poor choice can lead to delays, quality issues, and lost revenue. But how do you avoid these pitfalls? Let’s dive into the 5 key metrics that will help you make the right decision.

Snippet paragraph: The right custom insole supplier1 ensures quality, cost-efficiency, and long-term partnerships, saving you time and money.

When I first started working with Footcool, I was amazed at how their expertise transformed our product line. Their attention to detail and commitment to quality set them apart. Let’s explore the key metrics you need to consider when choosing a supplier.

1. What Are the Supplier’s Technical Capabilities?

Technical capabilities are the backbone of any custom insole supplier. Without advanced technology and expertise, even the best designs can fall short.

Snippet paragraph: A supplier’s technical capabilities2 determine their ability to produce high-quality, customized insoles that meet your specific needs.

Dive Deeper: Evaluating Technical Capabilities

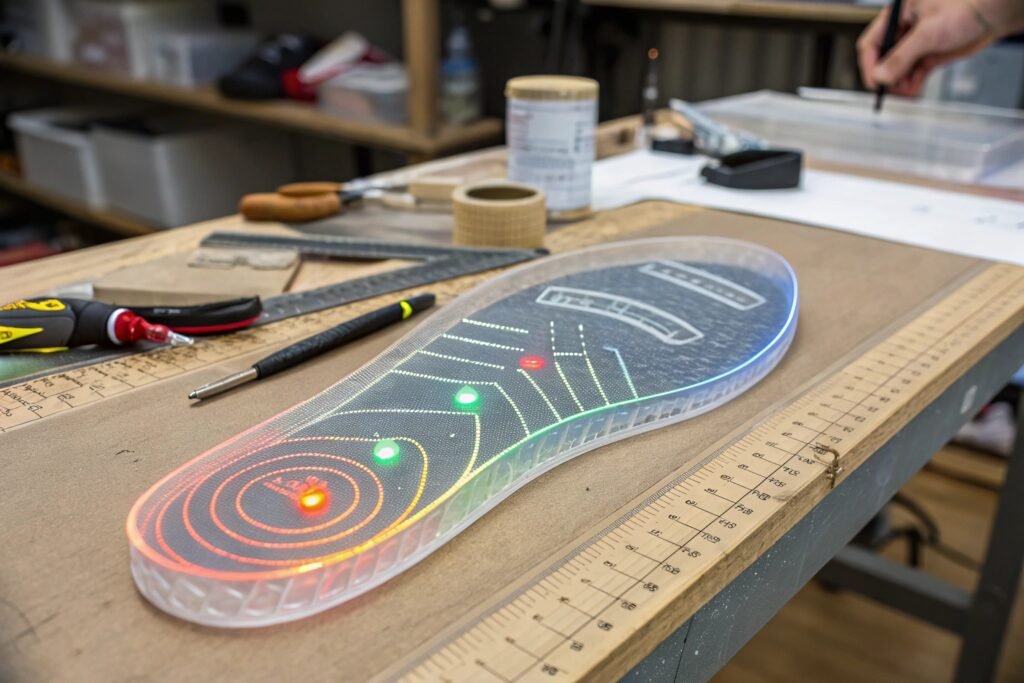

- Modern Manufacturing Methods: Does the supplier use 3D printing or other advanced techniques? These methods ensure precision and efficiency, especially for complex designs like medical-grade or athletic insoles.

- R&D Capabilities: A supplier with strong R&D can innovate and improve continuously, ensuring your products stay ahead of the competition.

- Customization: Can they handle unique designs tailored to specific needs? This is crucial for brands targeting niche markets.

Think of it like choosing a chef who can perfectly cook your favorite dish, no matter how unique it is.

2. What Is the Minimum Order Quantity (MOQ) and Scalability?

Snippet paragraph: MOQ and scalability determine whether a supplier can meet your current needs and grow with your business.

Dive Deeper: MOQ and Scalability Considerations

- Minimum Order Quantity: Does the supplier’s MOQ align with your business size? Small batches are ideal for niche markets, while large-scale production suits mass-market brands.

- Scalability: Can they increase production as your business grows? This flexibility is crucial for long-term partnerships.

It’s like buying groceries—you need a store that offers both small packs for everyday use and bulk options for special occasions.

3. Does the Supplier Have the Right Certifications and Compliance?

Snippet paragraph: Certifications and compliance ensure the supplier meets industry standards and ethical practices, protecting your brand’s reputation.

Dive Deeper: Certification and Compliance

- Industry Standards: Look for certifications like ISO, which indicate a commitment to quality.

- Environmental and Ethical Practices: Ensure the supplier complies with environmental regulations and ethical sourcing practices.

- Safety and Regulatory Requirements: Check their track record for meeting safety standards.

It’s like hiring a babysitter—you want someone with proper training and a clean background check.

4. Is the Pricing Transparent and Cost-Efficient?

Snippet paragraph: Transparent pricing and cost efficiency ensure you get the best value without compromising quality.

Dive Deeper: Pricing and Cost Efficiency

- Pricing Structure: Is the pricing clear, including hidden costs like shipping or setup fees?

- Long-Term Benefits: Does the supplier offer discounts for bulk orders or reduced lead times through efficient production methods?

- Total Cost of Ownership (TCO): Consider maintenance and replacement costs to evaluate the true cost.

It’s like buying a car—you don’t just look at the sticker price but also fuel efficiency and maintenance costs.

5. How Reliable Is the Supplier’s Delivery Performance and Responsiveness?

Snippet paragraph: Reliable delivery and responsiveness ensure your products reach customers on time, maintaining your brand’s reputation.

Dive Deeper: Delivery and Responsiveness

- On-Time Delivery: What is their on-time delivery rate, and how do they handle urgent orders?

- Communication: Are they responsive to queries or issues, offering proactive updates during production?

- Logistics: Check their logistics capabilities, including proximity to your location for faster delivery.

It’s like ordering pizza—you want it hot, fresh, and delivered on time!

Conclusion

Choosing the right custom insole supplier is like building a partnership—it requires trust, clear communication, and shared goals. Use these 5 key metrics as a checklist to evaluate potential suppliers and avoid common pitfalls.

-

Explore this resource to understand the essential criteria for selecting a reliable custom insole supplier, ensuring quality and efficiency in your business. ↩ ↩

-

This link will provide insights into the importance of technical capabilities in producing high-quality custom insoles, crucial for your footwear business. ↩