Custom orthotic insoles are transforming the footwear industry by delivering unparalleled comfort and support. But here’s the catch: manufacturing these insoles efficiently, accurately, and at scale has long been a challenge. Enter the visualized production process — a game-changing approach that redefines how orthotics are designed, produced, and delivered.

A visualized production process streamlines custom orthotic insole manufacturing by combining precision, transparency, and seamless client collaboration.

Let’s break down how this innovative method is reshaping the industry.

Table of Contents

ToggleThe Visualized Workflow: A Step-by-Step Breakdown

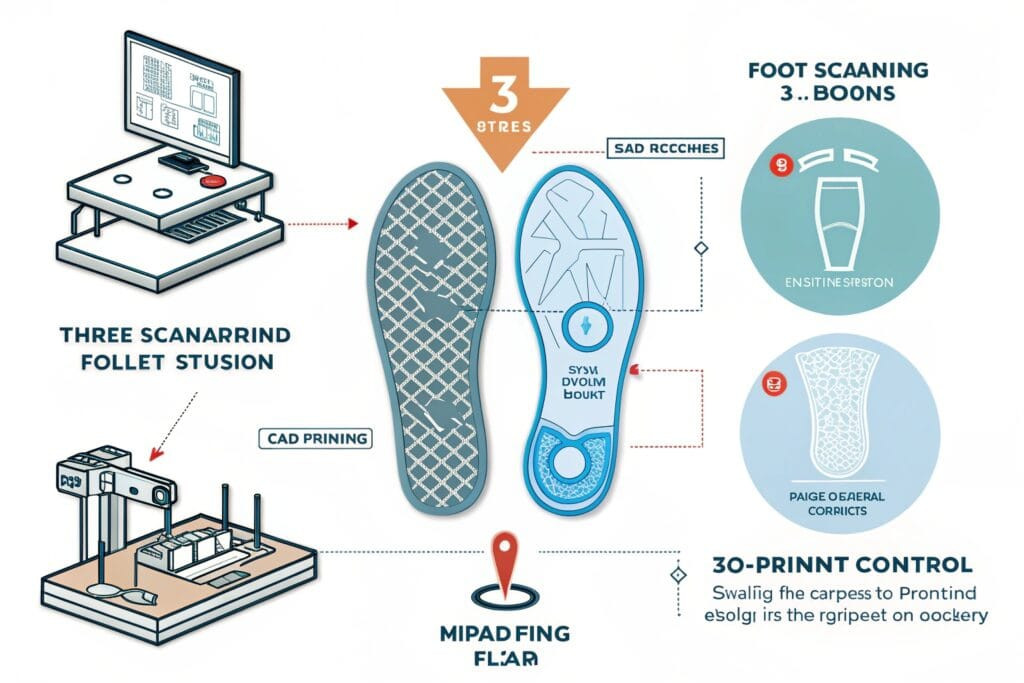

At its core, a visualized production process is all about clarity and control. By mapping out every stage — from foot scanning to 3D printing — manufacturers gain the tools to create tailored insoles more efficiently than ever.

The process is built on three key pillars: foot scanning, CAD-based design, and 3D printing with rigorous quality control.

Step 1: Foot Scanning for Unmatched Precision

Think of foot scanning as the blueprint of custom insole production. Using advanced tech like iPhones or dedicated scanning devices, detailed 3D models of the foot are captured. This ensures every insole is tailored to meet individual needs.

Accurate foot scans remove guesswork, setting the foundation for a flawless production process.

For example, open-source scanning software and cutting-edge tools can detect subtle variations in foot structure — whether it’s accommodating flat feet, high arches, or other biomechanical nuances. Choose your equipment based on your budget and scale, and enjoy consistently high-quality results.

Step 2: CAD Tools for Seamless Insole Design

Once the foot has been scanned, the next step is designing the insole using CAD (Computer-Aided Design) software. Industry go-to solutions like LutraCAD, Sneakprint, and Leopoly allow manufacturers to transform foot data into precise 3D models, ready for production.

These tools optimize designs for comfort, performance, and durability.

Even better, CAD tools enable real-time adjustments and performance simulations, allowing manufacturers to troubleshoot and refine their designs before production begins. The result? Fewer errors, faster turnaround times, and happier clients.

Step 3: 3D Printing for Efficiency and Customization

3D printing has revolutionized how custom orthotic insoles are produced. This technology offers unmatched precision, speed, and flexibility compared to traditional manufacturing methods. Companies like Feetneeds are leveraging AI-powered 3D printing to push the boundaries even further.

With 3D printing, you can produce high-quality, fully customized insoles at scale — without sacrificing speed or accuracy.

Quality control is the final piece of the puzzle. Each insole undergoes meticulous checks to ensure it matches the client’s specifications. By combining AI-driven processes with human oversight, manufacturers can deliver consistent results every time.

The Benefits of a Visualized Production Process

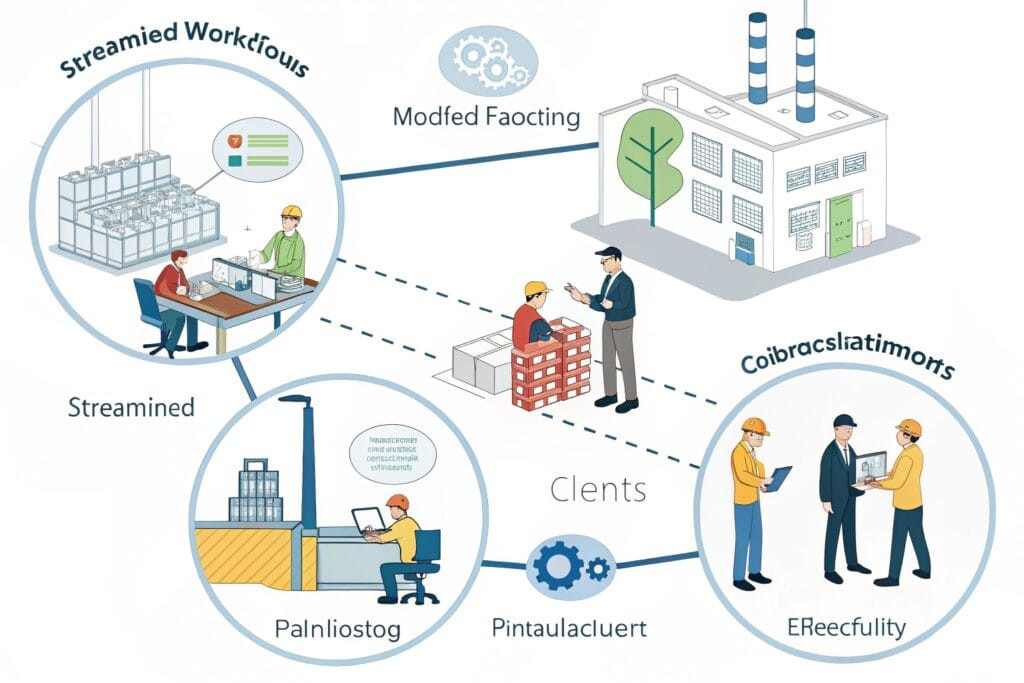

A visualized production process isn’t just about streamlining workflows — it’s about transforming how manufacturers and clients collaborate. By incorporating transparency and innovation, this approach delivers results that traditional methods simply can’t match.

Here’s why visualized production is a game-changer:

Simplifying Complexity

One common misconception is that advanced manufacturing methods are overly complicated. But the truth? A visualized workflow simplifies every aspect of the process. With clear, step-by-step visual updates, clients can see exactly how their insoles are being developed.

Compared to conventional workflows, this approach is faster, more adaptable, and significantly less wasteful.

By demystifying the process, manufacturers can foster stronger relationships with clients, while also showcasing the efficiency of their methods.

Transparency = Trust

When clients can see how their insoles are designed and produced, it builds trust. This transparency not only enhances client satisfaction but also encourages valuable feedback, leading to continuous improvement.

In short, transparency ensures that the final product meets — or exceeds — expectations.

For instance, visual updates during the design phase allow clients to flag concerns early, eliminating the risk of costly revisions or delays. The result? A smoother, faster production process that aligns with the client’s vision.

The Future of Custom Orthotic Insoles: Innovation on the Horizon

The visualized production process is just the beginning. With advancements in technology, the future of custom orthotic insoles looks brighter than ever.

Emerging trends like smart sensors, sustainable materials, and AI-driven designs are set to redefine comfort and functionality.

What’s Next for Custom Insoles?

Smart Sensors

Imagine insoles embedded with sensors that monitor foot pressure in real time. This data could enable even more personalized designs tailored to your specific needs.Eco-Friendly Materials

Biodegradable materials are making waves in the industry, offering sustainable solutions that don’t compromise on durability or performance.AI-Powered Customization

AI-driven tools will make designing and personalizing insoles faster, more efficient, and more accurate than ever before.

These innovations aren’t just about improving the product — they’re about aligning with global trends of sustainability, personalization, and cutting-edge technology.

Wrapping It Up

A visualized production process is more than a manufacturing technique; it’s a fundamental shift in how custom orthotic insoles are created and delivered. By combining precision, transparency, and innovation, manufacturers are setting new standards for quality and efficiency.

Whether you’re a manufacturer looking to streamline your workflows or a client seeking the perfect fit, the visualized approach is the way forward.

Ready to collaborate or learn more? Drop us a line at contact@insolework.com. Let’s shape the future of custom orthotic insoles together!