Are custom insoles worth their price tag? Many people wonder if investing in these shoe inserts brings real value. Let’s explore the costs, benefits, and long-term advantages of custom insoles to find out.

Custom insoles may cost more upfront but deliver long-term value through foot health, comfort, and customer loyalty.

Custom insoles aren’t just another accessory. They’re a solution to foot pain and discomfort. Let’s dive deeper into their production cost1s, pricing, and the benefits they bring over time.

Table of Contents

ToggleWhat are custom insoles, and why choose them?

Custom insoles are made specifically for your feet, offering benefits regular insoles can’t. But why are they an investment worth considering?

Custom insoles provide personalized comfort, improve foot health, and alleviate specific problems like flat feet or plantar fasciitis.

Dive deeper: Why custom insoles matter

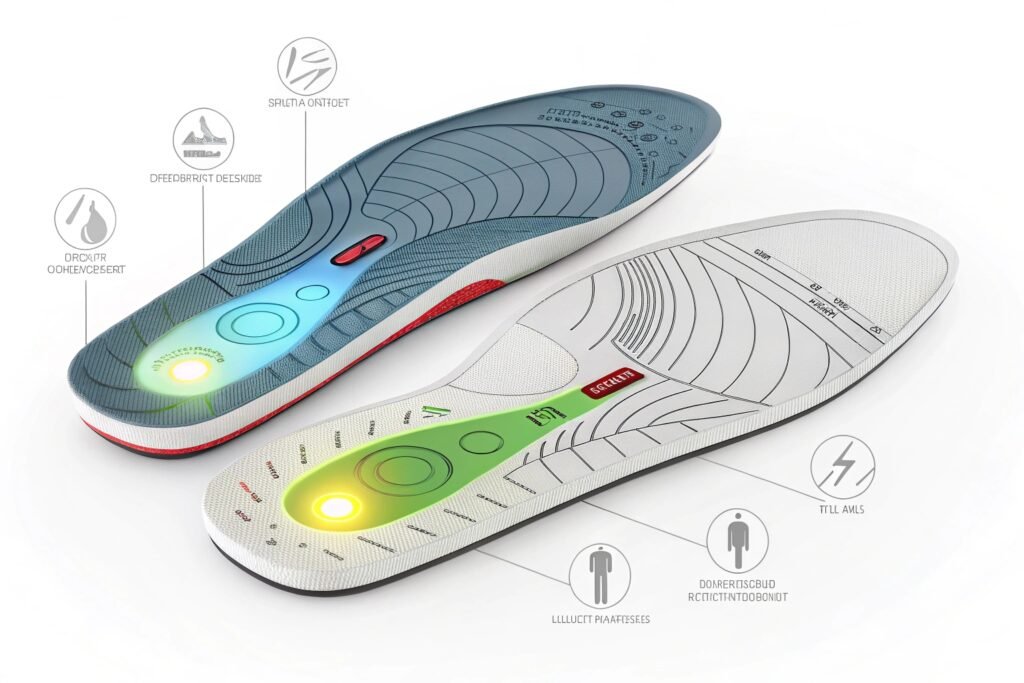

Custom insoles are different from off-the-shelf options because they’re tailored to your unique foot shape and needs. Whether you have high arches or flat feet, these insoles provide precise support. They also reduce foot fatigue, improve posture, and help prevent foot-related issues like bunions or heel spurs.

Key benefits of custom insoles:

| Benefit | Explanation |

|---|---|

| Personalized Fit | Crafted for individual foot shapes. |

| Pain Relief | Targets specific issues like plantar fasciitis. |

| Durability | Made with high-quality materials. |

In my experience, I’ve seen customers rave about how custom insoles transformed their walking and exercise routines. This makes them especially valuable for those who spend long hours on their feet.

How much do custom insoles cost to make?

Custom insoles aren’t mass-produced, which makes their production process unique. But how much does it really cost?

Producing custom insoles involves precise materials, advanced technology, and skilled labor, which increases their cost.

Custom insoles are often made using materials like PTV or HBT, which enhance durability and comfort. Additionally, the manufacturing process includes scanning, molding, and refining to ensure a perfect fit.

Dive deeper: Comparing costs of production

Producing custom insoles requires more attention to detail than standard ones. Here’s a quick comparison:

| Cost Factors | Custom Insoles | Regular Insoles |

|---|---|---|

| Materials | High-quality, durable | Basic foam or gel |

| Technology | Advanced scanning and molding | Basic factory molds |

| Labor | Skilled craftsmanship | Mass production workers |

| Unit Cost | Higher | Lower |

While custom insoles cost more to produce, the added value they bring justifies the investment. From my perspective, the cost is a small price to pay for pain-free movement and better foot health.

How much can you sell custom insoles for?

Selling custom insoles is a great opportunity for higher profits. But how can you decide on the right price?

Custom insoles can be priced significantly higher than regular ones due to their personalized features and added benefits.

In the B2B market, prices often reflect the materials used, the level of customization, and the target audience. For instance, insoles for sports shoes may have a higher price point due to their performance-enhancing features.

Dive deeper: Pricing and profit potential

Let’s break down how pricing works. Custom insoles typically sell for 2-3 times the cost of production. Why? Because customers see them as a premium product that solves real problems. Here’s an example:

| Type of Insole | Production Cost | Selling Price | Profit Margin |

|---|---|---|---|

| Custom Sports Insole | $15 | $60 | $45 |

| General Comfort Insole | $10 | $30 | $20 |

With Footcool’s ability to deliver high-quality insoles tailored to specific needs, the profit margins are an attractive prospect for businesses aiming to expand their product line.

Why is the customer lifetime value2 higher for custom insoles?

Customer loyalty is crucial for business. But why do custom insoles encourage repeat purchases?

Customers who experience the comfort and benefits of custom insoles are more likely to return for replacements or recommend them to others.

The personalized nature of custom insoles builds trust. When a customer finds relief from foot pain or improved performance in sports, they see value in the product and stay loyal.

Dive deeper: Building loyalty through quality

Repeat customers aren’t just buying another insole. They’re investing in a better quality of life. Here’s why the lifetime value of these customers is higher:

Key drivers of customer loyalty:

- Positive Experience: Customers feel the difference in comfort and performance.

- Trust in Quality: High-quality materials ensure durability and satisfaction.

- Word of Mouth: Satisfied customers recommend the product, bringing in new buyers.

For example, in my interactions with shoe brands, I’ve noticed that customers often request Footcool insoles after trying them once. This repeat business not only boosts revenue but also strengthens brand loyalty.

Why custom insoles are a good choice?

Custom insoles may have higher upfront costs but deliver long-term benefits. Their ability to enhance foot health, improve comfort, and drive customer loyalty makes them a worthwhile investment for both customers and businesses.